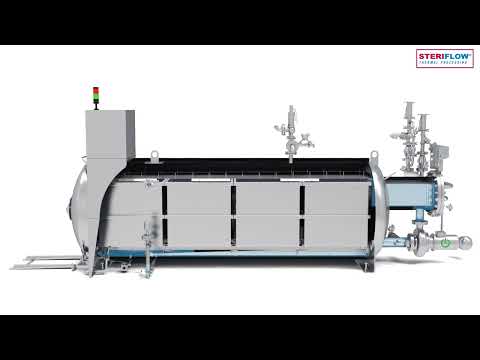

Techno Pak offre des machines pouvant faire de la stérilisation ou de la pasteurisation par ruissellement d’eau. Cette méthode innovante permet une plus grande économie d’énergie et d’eau, puisqu’elle est réutilisée, comparativement aux systèmes à vapeur ou à immersion. La stérilisation permet à vos produits de conserver une grande qualité, et ceux-ci ne sont pas altérés.

Types de stérilisation

Notre gamme de stérilisateurs par ruissellement est complète avec la stérilisation statique, en rotation, avec brassage (rocking) ou par va et vient (jusqu’à 100 cycles par min). Demandez à nos experts pour vous conseiller en fonction de votre produit.