Notre gamme d’étiqueteuses convient à divers emballages de produits. Nos modèles sont faciles à utiliser, et le chargement des rouleaux d’étiquettes se fait très rapidement. Elles vous confèrent une application parfaite de votre image de marque sur toutes grandeurs de surfaces.

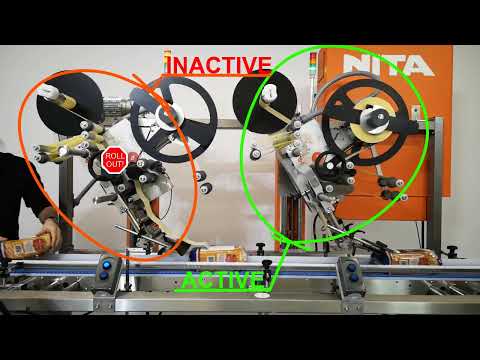

Multiples côtés

Nos modèles d’étiqueteuses pour multiples côtés (aussi appelées multiface) vous permettent d’appliquer des étiquettes adhésives sur divers produits. Ils apposent l’étiquette simultanément sur plusieurs côtés du produit. Ce type de machine est utilisé pour des produits ayant 2 étiquettes et plus.

Wrap around

Nos modèles d’étiqueteuse wrap around permettent d’apposer des étiquettes adhésives sur des bouteilles cylindriques, des conteneurs, des pots et des boîtes de conserve.

Imprimante applicatrice

Nos modèles d’imprimante applicatrice permettent d’imprimer des étiquettes et de les apposer sur vos produits dans un seul et même processus. L’application de l’étiquette peut se faire dans n’importe quelle position, sur des produits stationnaires ou en mouvement.

Besoin d'aide pour trouver le produit qui vous convient?